AINavi Function Features

AI Defect Detection

In many manufacturing applications for defect detection, the AI technology commonly referred to is a specific branch of AI known as deep learning. Deep learning utilizes neural network architectures, employing a method of feature searching and learning through the provision of extensive datasets. Unlike AOI, which requires designing specific parameter rules for each potential pattern of defects, AI simply requires the provision of diverse defect image data for the model to automatically learn. This approach significantly reduces program development time.

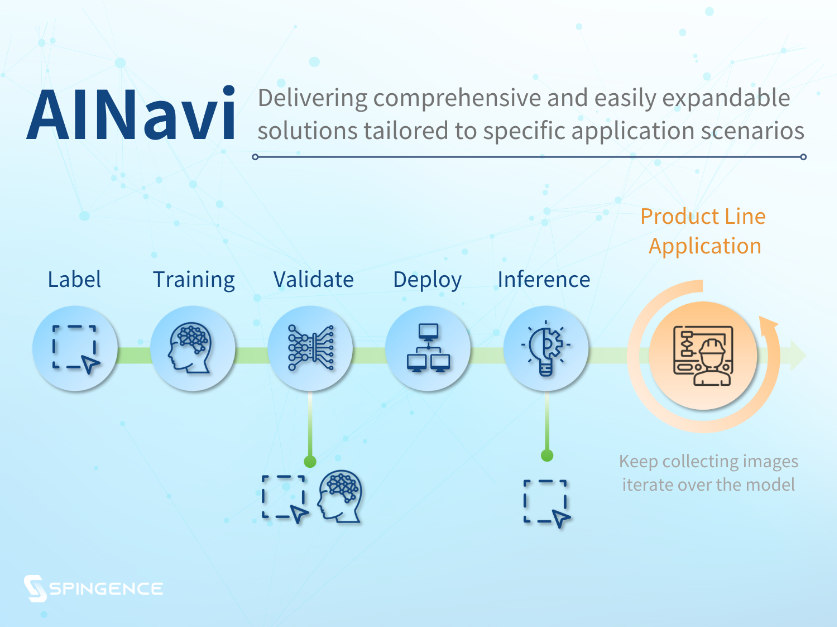

AINavi - Integrating expertise to shape processes unleashes the limitless potential of AI on the production line.

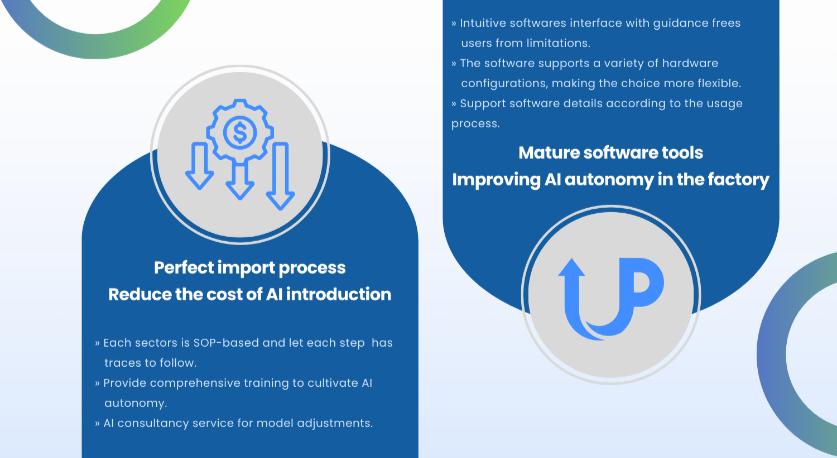

AINavi is a deep learning visual inspection software designed by Spingence, specifically for the manufacturing industry. It enables the practical implementation of AI to meet the diverse needs of manufacturing production lines, including the complexity of products and low tolerance for defects. The software features an intuitive interface design, allowing users to quickly familiarize themselves with the system. With guided steps, users can effortlessly and rapidly complete the training, validation, and deployment of AI models. Additionally, it supports self-operated maintenance.

In order to unlock the limitless value of AI and solve the long-standing bottlenecks in customer production and processes, Spingence has transformed expertise into a systematic approach. AINavi is designed as a detection software with several highlights to significantly assist customers in digital transformation and streamline production line management:

1. Project-based management: Maximizing flexibility in capital utilization

Replaces the previous model-oriented management approach with a project-based approach. Model and graphic management are separated, retaining the flexibility of asset utilization and greatly reducing the burden on memory. Users can utilize the training set repeatedly or more diversely, quickly selecting the required images for different levels of model training, and manage them flexibly to better achieve the detection goals.

2. Flexible Model Iteration: Evolving from Experience

Provides a flexible software architecture that allows users to easily trace back to any previous training step. Expand the training set or adjust the training parameters at any time to instantly tune the model to better meet the needs of the production line.

3. Open Production System: Compatible with multivariate models

In addition to the various algorithms optimized by Spingence for industrial inspection purposes, we also provide third-party model importing capabilities, allowing users to import self-developed models. While combining our own AI development capabilities, we provide excellent and convenient software to save resources and time for enterprise development and maintenance.

4. Inferred Values Personalization : Get the best judgment in real time.

Customized inference thresholds can be adjusted according to the actual needs of the inspection to ensure the fastest possible results in different scenarios and inspection standards.

AINavi is a solution to the pain points encountered by users in practical applications, such as model effect, time-consuming annotation, and detection standard variations;The one-stop platform can help customers smoothly complete the training, testing and deployment of deep learning models, including: character detection, classification, object detection, segmentation, anomaly detection, etc. to meet the vast majority of industrial application scenarios, so that enterprises can quickly build the model and continue to optimize it for all types of products and scenarios of the customization needs to accelerate the flexibility and efficiency of the enterprise's smart manufacturing.

Please feel free to cantact salesinfo@spingence.com, let Spingence provide you the most suitable solution!