AINavi New Function | NaviFlow

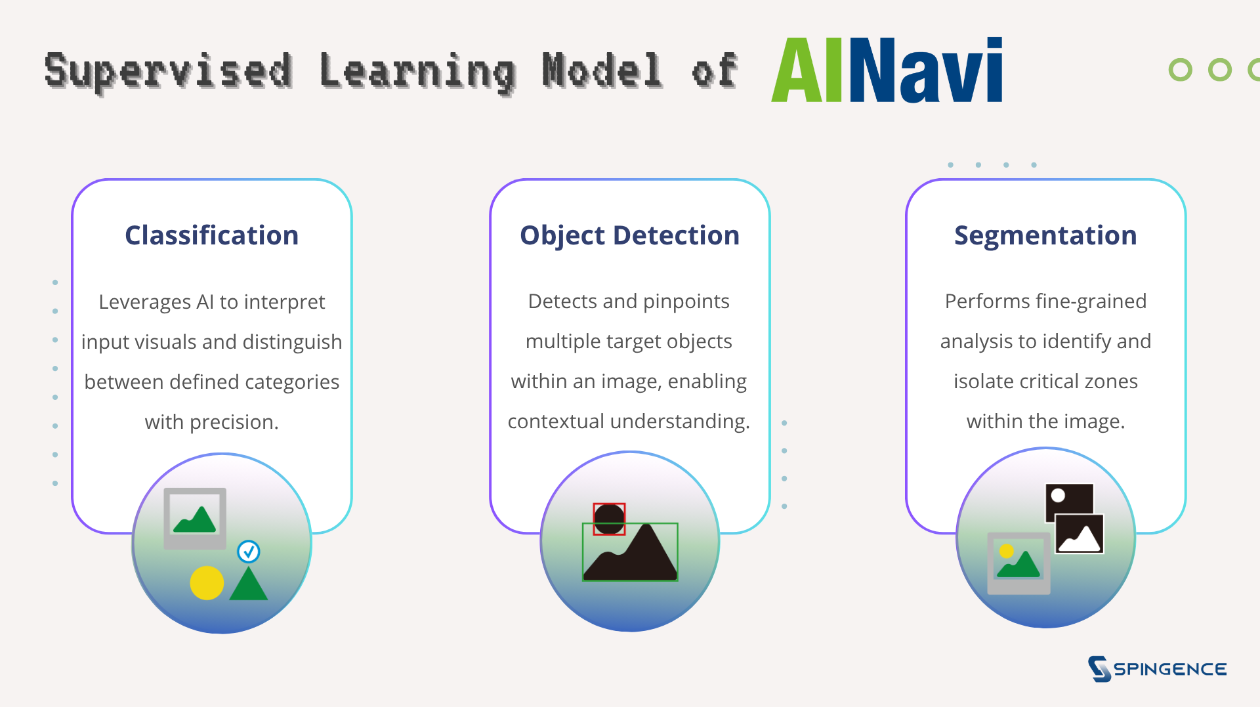

To meet the diverse needs of different product types, AINavi offers three industrial-optimized supervised learning models: Classification, Object Detection, and Image Segmentation. This allows customers to select the most suitable deep learning model based on defect characteristics and inspection requirements—ensuring product quality while boosting production efficiency.

Inspection Challenges and Strategies of MLCC

As market demands become increasingly diverse, manufacturing environments face a growing variety of product types and defect patterns. For many production lines, it has become standard practice to define multiple inspection criteria for a single product. One prime example is one kind of passive components, Multilayer Ceramic Capacitors (MLCCs) that require inspection of both the ceramic body and electrode areas, each with its own set of defect types and standards. To meet these complex and precise inspection requirements, manufacturers have traditionally relied on chaining multiple AI models.

However, this multi-model architecture comes with several technical challenges:

1. Complex Preprocessing Needs:

MLCCs feature two distinct visual regions—ceramic and electrode—with significantly different background colors and highly similar defect characteristics. For instance, scratches on the ceramic area may resemble metal grain textures on the electrodes, leading to potential false detections. To simplify model learning, image preprocessing and region cropping are often required. But relying on a single model increases the risk of over-detection, potentially causing unnecessary yield loss. Additionally, frequent image preprocessing tasks can put a heavy load on CPU resources.

2. Visually Similar but Functionally Different Defects:

Dents and stains on the ceramic surface may appear visually similar, yet they represent different defect categories. Using a single model to detect both can compromise accuracy and limit the model’s effectiveness.

3. CT Latency and Performance Bottlenecks:

A single MLCC image may contain more than ten defect types, requiring identification through multiple AI models or AOI machines. This significantly slows down inspection speed, degrades model performance, and drives up system maintenance costs.

NaviFlow | An Innovative Solution to Overcome Multi-Model Integration Bottlenecks

To overcome the challenges of complex AI inspection workflows, Spingence has introduced NaviFlow—a powerful feature within the AINavi platform. With its intuitive, visual interface, NaviFlow empowers users to design inspection pipelines through simple drag-and-drop actions. It streamlines multi-model integration, image preprocessing, and model maintenance, enabling faster deployment and higher operational efficiency.

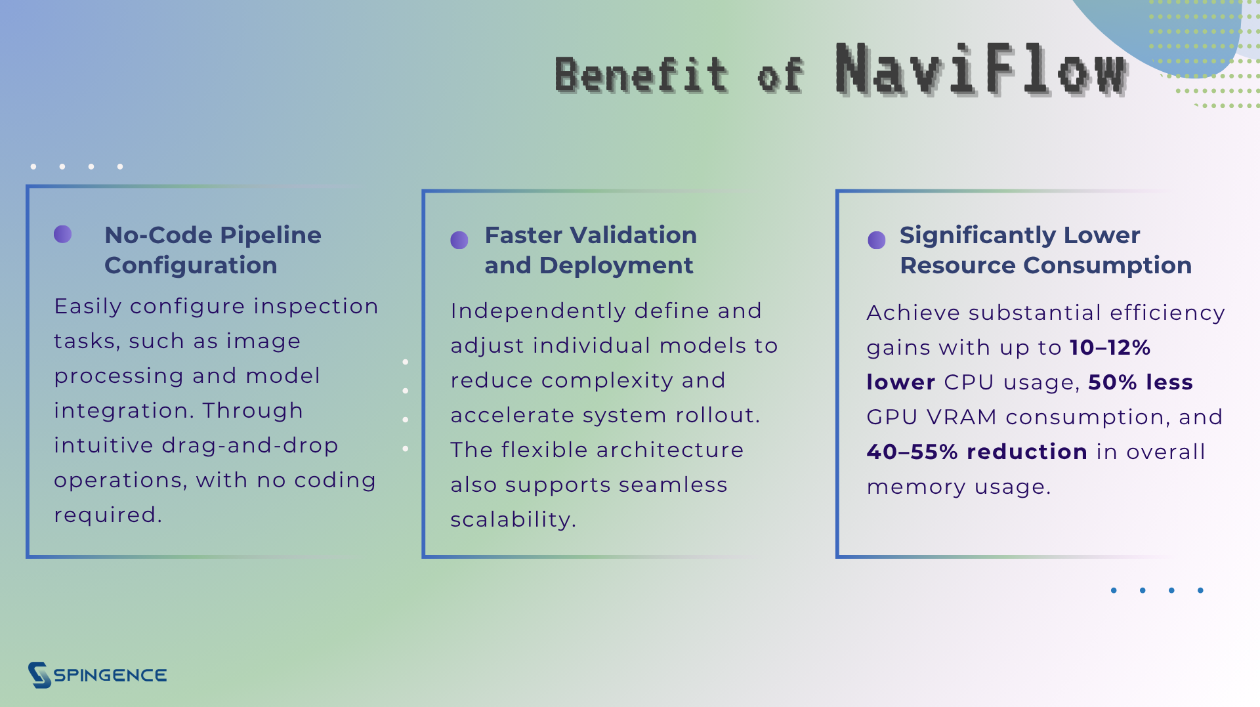

1. No Code Pipeline Configuration:

With NaviFlow, users can easily configure inspection tasks, such as image preprocessing, multiple AI model execution, and post-processing without any programming skills. The drag-and-drop interface greatly lowers the barrier to entry and simplifies operations for production teams.

2. Faster Validation and Deployment:

Each AI model within NaviFlow can be managed independently, making fine-tuning, dataset adjustments, and parameter optimization much more efficient. This modular design improves system scalability and allows teams to quickly identify and resolve performance issues. As a result, cycle time can be reduced by up to 20–25%.

3. Significantly Lower Resource Consumption:

NaviFlow significantly optimizes system resource usage. Depending on the number of integrated models and preprocessing/post-processing tasks, GPU VRAM usage can be reduced by up to 50%, and system memory consumption by 40–55%. These improvements not only enhance hardware efficiency but also reduce overall system load.

Get in touch with Spingence to learn how AINavi can be seamlessly deployed to your production line. Improve inspection efficiency and let NaviFlow simplify AI model orchestration. We’re here to help you accelerate your path to smarter, more precise manufacturing—unlocking new business value and boosting your competitive edge.