AOI (Automated Optical Inspection) is a high-speed, high-precision optical image inspection system that utilizes machine vision with Rule-Based algorithms as the basis for measuring the dimensional specifications of finished products, semi-finished products, or for detecting abnormalities such as foreign object attachment and appearance defects. In automated production lines, product appearance inspection used to take a lot of manpower, and in order to take into account the production capacity, it is often difficult to execute 100% product inspection. AOI can improve the shortcomings of the traditional manual inspection using optical instruments. Moreover, it can improve the stability of inspection quality and significantly shorten the inspection time, thus reducing the production cost.

AI, which is often compared with AOI, usually refers to Deep learning, one of the branches of AI. It's a method that uses a neural network architecture to search and learn features repeatedly by providing a large amount of data.In this framework, unlike AOI, which needs to design parameter rules for each kind of defects, AI only needs to provide as much information as possible.Instead, the AI only needs to provide as many defect images as possible, and the model learns them automatically, which greatly reduces the program development time.

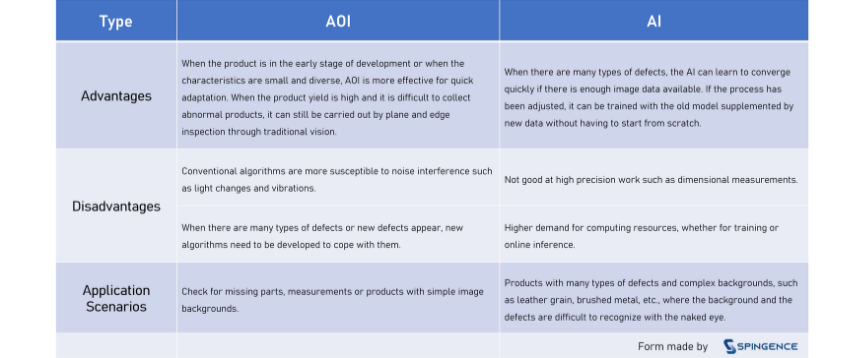

Although AOI and AI are often compared together, they are not substitutes but complementary. Since the inspection principle of AOI is to make logical judgment based on set parameters, over-screening has been a persistent problem in industries with more stringent external standards. In order to solve this problem, a second re-inspection has to be performed manually, which is not only time-consuming but also increases the inspection cost.

The maturity of AI technology can compensate for the shortcomings of AOI, improve inspection efficiency and effectively reduce overkill. In the early stage of AI introduction, when the amount of data is relatively small, it is difficult to ensure the accuracy of the actual implementation, and AOI can assist in the rapid collection of data and shorten the time of model convergence, which is why "AOI+AI" has gradually become a mainstream method to improve the accuracy of detection.